Die Line

The primary material used to make pizza boxes or printed pizza boxes is corrugated paper. Three-ply corrugated sheets are used to make these boxes. The corrugated pizza box must be excellent for transporting food, very resilient, inexpensive, stackable, thermally insulated to control humidity, and sturdy. Additionally, it offers room for branding. Cardboard sheets are typically used as pizza packaging because they are lightweight, inexpensive, and easy to deal with while still having the necessary structural integrity to hold and distribute pizzas. Both single wall corrugated board and solid cardboard are employed. E flute size corrugated cardboard is commonly used, however thicker B flute cardboard is also utilized. Pizza is an Italian savory dish made of a typically rounded, flattened foundation of wheat-based dough that is topped with tomatoes, mozzarella, onion, paneer, chicken, and frequently other ingredients. The pizza box, also known as the pizza package, is a cardboard folding box used to store hot pizzas for takeout. The printed pizza box is designed to convey a baked pizza with the least amount of quality loss. This signifies that the box must do two difficult-to-combine tasks: On the one hand, in order to keep the pizza warm, the box should provide the best insulation against the chilly air outside, the odd gust of wind, and heat radiation. The box must close tightly to prevent heat loss and maintain the warmth inside. Customers believe that the best temperature for eating pizza is between 70 and 85°C.

The primary material used to make pizza boxes or printed pizza boxes is corrugated paper. Three-ply corrugated sheets are used to make these boxes. The corrugated pizza box must be excellent for transporting food, very resilient, inexpensive, stackable, thermally insulated to control humidity, and sturdy. Additionally, it offers room for branding. Cardboard sheets are typically used as pizza packaging because they are lightweight, inexpensive, and easy to deal with while still having the necessary structural integrity to hold and distribute pizzas. Both single wall corrugated board and solid cardboard are employed. E flute size corrugated cardboard is commonly used, however thicker B flute cardboard is also utilized. Pizza is an Italian savory dish made of a typically rounded, flattened foundation of wheat-based dough that is topped with tomatoes, mozzarella, onion, paneer, chicken, and frequently other ingredients. The pizza box, also known as the pizza package, is a cardboard folding box used to store hot pizzas for takeout. The printed pizza box is designed to convey a baked pizza with the least amount of quality loss. This signifies that the box must do two difficult-to-combine tasks: On the one hand, in order to keep the pizza warm, the box should provide the best insulation against the chilly air outside, the odd gust of wind, and heat radiation. The box must close tightly to prevent heat loss and maintain the warmth inside. Customers believe that the best temperature for eating pizza is between 70 and 85°C.Paper Material

Finishing

Some introductions about pizza boxes

Video

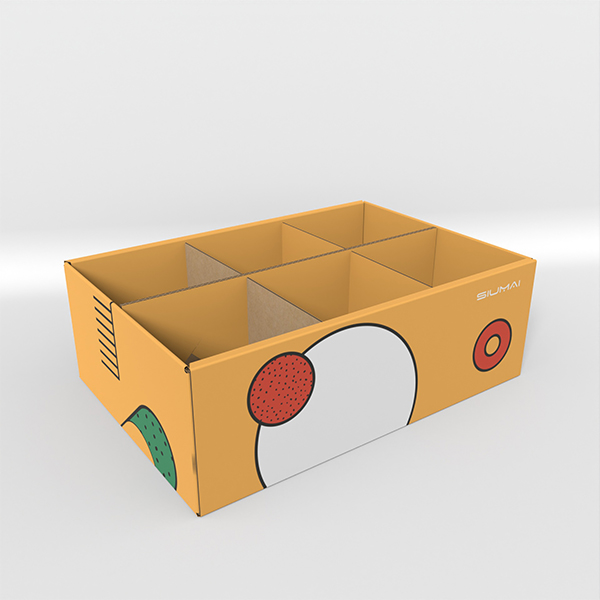

| Box Style | Wholesale Pizza printed box pizza mailer box |

| Dimension (L + W + H) | All Custom Sizes Available |

| Quantities | No MOQ |

| Paper choice | White cardboard, Karft paper, [ABCDEF] Flute Corrugated, Hard grey board, Laser paper etc. |

| Printing | CMYK Colors,Spot color printing [All use environmentally friendly UV inks] |

| Finishing | Gloss Lamination, Matte Lamination, Matt varnishing, Glossy varnishing, Spot UV, Embossing, Foiling |

| Included Options | Desgin, Typesetting, Coloring match, Die Cutting, Window Sticking, Glued, QC, packaging, Shipping, Delivery |

| Additional Options | Embossing, Window Patching, [Gold/silver] Foil Hot Stamping |

| Proof | Die line, Flat View, 3D Mock-up |

| Delivery time | When we receive the deposit, it takes 7-12 business days for producing the boxes. We will reasonably arrange and plan the productioncycle according to the quantity and material of the boxes to ensure on-time delivery. |

| Shipping | Shipping transports, Train transports, UPS, Fedex, DHL, TNT |

Specifications